|

1 Comment

Unique 3D chipbreaker formed with a laser processing machine

Here's a great video on how to check for runout out in your steep taper CAT40, CAT50 ER collet chucks.

What makes Coolube® unique? Using the right lubricant is very important in MQL applications. The perfect metal cutting fluid will adhere to the surface of the tool and provide a thin, low friction barrier between the cutting tool and work piece. Studies have shown that Coolube® has superior properties which make it an ideal lubricant. Coolube’s® polar properties create a strong consistent bond between Coolube® and metallic surfaces. This creates an even, strong, and durable layer of lubrication. Coolube® reduces friction 50% better than typical mineral oils preventing heat buildup and resulting in longer tool life and a superior cut finish. Unist MQL application systems

Environmental impact of metal cutting fluidCoolube’s® 100% natural, non-toxic, renewable plant oil-based composition makes it an ideal choice for manufacturers who care about their environmental impact. Coolube® contains no petroleum products, is 100% chlorine and silicone free and produces no harmful VOC’s. Coolube® is completely biodegradable, yet still has a long shelf life. Impact on your shopCoolube® is as good for your shop as it is for the global environment. Its non-toxic formula is safe for workers and will not cause dermatitis. Implementing MQL metal cutting fluid with Coolube® also eliminates coolant spills and overspray resulting in dry machines and floors and improved safety conditions. Impact of metal cutting fluid on your bottom lineCoolube® is one of the most cost-effective metal cutting fluids available when you consider the amount of Coolube® required and the additional benefits it offers. Coolube® is most effective when applied sparingly. In a typical operation, the amount of Coolube® consumed in an eight hour shift is only a few ounces. This is in stark contrast to traditional flood coolant systems that require gallons of coolant, coolant filtering, testing, treatment, and disposal. Replacing a flood coolant system with Coolube® and a Unist MQL system eliminates these costs while often increasing tool life and improving surface finish. Additional savings include reduced housekeeping/cleaning costs and an increase in the recycling value of chips because they are clean and dry.

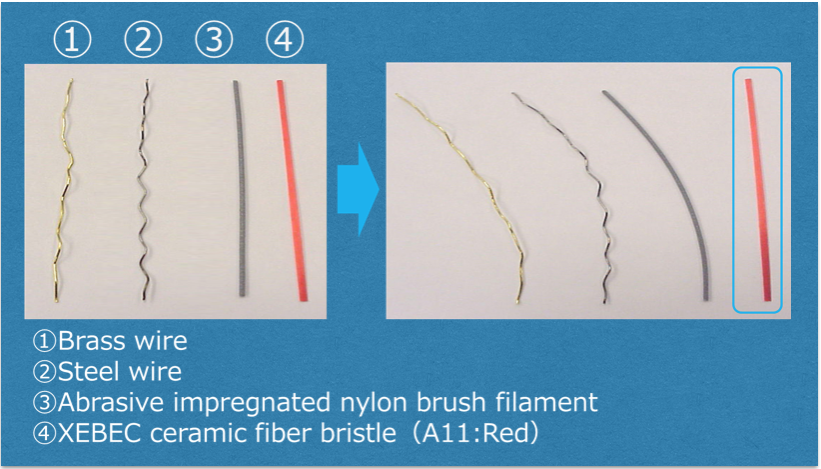

Xebec Technology Co., LTD offers a wide range of deburring and surface finishing solutions that dramatically improve manufacturing productivity and greatly reduce costs. Xebec products utilize a unique, patented process to produce brushes, sticks and stones of solid ceramic fibers that simply outperform older technologies. The ceramic fibers are woven to create self-sharpening filaments that maintain consistent cutting action on the tips. Unlike wire and abrasive impregnated nylon brush filaments, the unique design of the Xebec fiber rod maintains its shape with no deformation even after repeated use. This leads to consistent performance time after time. Ceramic fiber products can be used in CNC, robotic or hand held devices on materials up to 65Rc for:

Amazing Polishing Ability Best achievable surface smoothness: Ra=0.1μm The superfine fibers, measured in micrometers, can improve surface roughness in a short time. Article originally appeared on Te-Co's Blog. It’s no secret U.S. students lag behind in math and science courses compared to many countries in Eastern Asian and Europe. Studies show it’s not just children who struggle with the subject: Between 50-89 percent of Americans suffer from some sort of math anxiety, and only 45 percent of high school graduates in 2011 were prepared for college-level mathematics.

The gap in understanding mathematics isn’t new in America, but more initiatives to combat this gap are popping up. It started in 1986 when April became known as Mathematic Awareness Month to encourage the study and increase awareness of mathematics. “The application of mathematics is indispensable in such diverse fields as medicine, computer sciences, space exploration, the skilled trades, business, defense, and government,” then-President Ronald Reagan said. “To help encourage the study and utilization of mathematics, it is appropriate that all Americans be reminded of the importance of this basic branch of science to our daily lives.” We know mathematics is vital—especially to us in the manufacturing industry. Without simple triangles and calculations we would not be able to design, program and machine the parts we sell. Being able to solve problems using algebra, geometry and trigonometry is at the core of our manufacturing processes. Utilizing mathematics is actually important to every aspect of our business. We us mathematics in selling, manufacturing, inspecting, and yes even counting the money made. But how can we expect to continue growing our manufacturing when students are struggling to meet these standards? Well, even more change is happening. Curriculum restructuring in many states across the country is adapting and suiting the specific needs of students while adhering to regulated guidelines. They not only study math skills but the concepts behind them along with applying mathematical reasoning. Plus, there are a slew of online tutorials and resources to aid the learning process. We are tapping into new resources, challenging ourselves, and expanding our brainpower—much like we do every day at TE-CO. Don’t fret, because U.S. manufacturing isn’t going anywhere. With many companies choosing to manufacture their products stateside, sales increasing, and manufacturing turning digital, the industry has been steadily rising. A new report from Georgetown University estimates there will be more than three million new manufacturing jobs available by 2018. Those are some good numbers to add up, right? We think the scope and process of mathematics is changing along the technology it is computed on, and we can’t help but be excited for the future of the subject matter and the positive impact it will have on the industry, our jobs, and our company. |

AuthorHere you will find the latest breaking news from manufacturing as well as the newest product introductions and promotions Archives

July 2017

Categories

All

|

HoursM-F: 8am - 5pm

|

Telephone319.329.8134

|

|

©2023 Abrasive Innovations. All Rights Reserved

RSS Feed

RSS Feed