Envision Tec

Innovation. Credibility. Value.

For 15 years, EnvisionTEC has been delivering advanced 3D printers and materials that are Made to Matter. Aerospace Engineers. MCAD designers. Doctors. Dentists. Laboratories. Researchers. Jewelers. Animators. When it’s a critical part — for use in flight, the human body, a wedding ring or Hollywood movie — serious professionals choose EnvisionTEC.

For 15 years, EnvisionTEC has been delivering advanced 3D printers and materials that are Made to Matter. Aerospace Engineers. MCAD designers. Doctors. Dentists. Laboratories. Researchers. Jewelers. Animators. When it’s a critical part — for use in flight, the human body, a wedding ring or Hollywood movie — serious professionals choose EnvisionTEC.

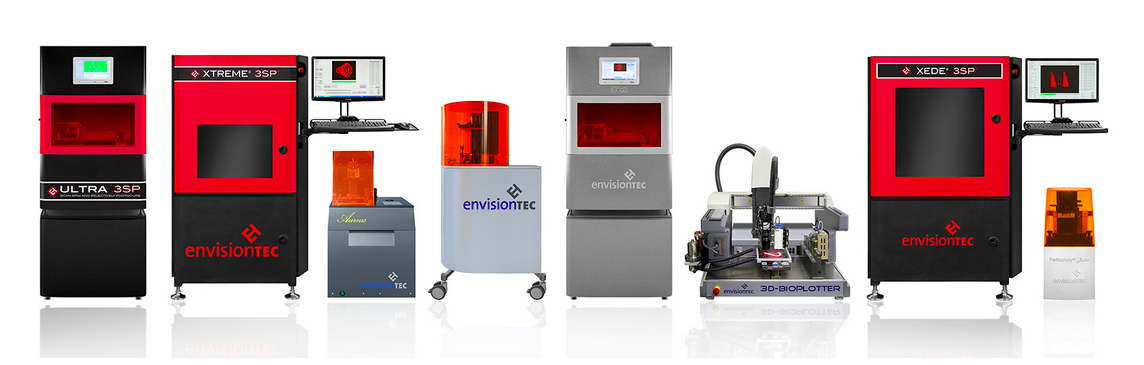

3D Printer Families

Since the founding of EnvisionTEC in 2002, with their pioneering DLP (Digital Light Processing) technology, they have been innovators in the 3D printing space. But they don’t innovate for the sake of innovation. They do it to solve the real-world problems of our customers – professionals who manufacture prototypes, tooling, parts and final products for demanding cost-sensitive customers in a variety of industries.

Today, they sell more than 40 models of 3D printers based on six distinct process technologies. Their printers are known for delivering excellent precision, surface finish, functionality and speed. And each of their families of printers below offers something special to meet the unique needs of thier fast-growing list of customers and the industries in which they operate. What could we help you print?

Since the founding of EnvisionTEC in 2002, with their pioneering DLP (Digital Light Processing) technology, they have been innovators in the 3D printing space. But they don’t innovate for the sake of innovation. They do it to solve the real-world problems of our customers – professionals who manufacture prototypes, tooling, parts and final products for demanding cost-sensitive customers in a variety of industries.

Today, they sell more than 40 models of 3D printers based on six distinct process technologies. Their printers are known for delivering excellent precision, surface finish, functionality and speed. And each of their families of printers below offers something special to meet the unique needs of thier fast-growing list of customers and the industries in which they operate. What could we help you print?

Desktop Family

Just because it sits on a desk doesn’t mean the EnvisionTEC line of desktop 3D printers is like other cheap tabletop models. It’s not even close. EnvisionTEC desktop 3D printer family uses advanced DLP technology backed by more than a decade of development and exclusive patent-protected processes.

EnvisionTEC offer build sizes up to 71.7 cubic inches and accuracy levels down to 30 microns. The printers in this family are powerful tools used by thousands of professionals worldwide.

Just because it sits on a desk doesn’t mean the EnvisionTEC line of desktop 3D printers is like other cheap tabletop models. It’s not even close. EnvisionTEC desktop 3D printer family uses advanced DLP technology backed by more than a decade of development and exclusive patent-protected processes.

EnvisionTEC offer build sizes up to 71.7 cubic inches and accuracy levels down to 30 microns. The printers in this family are powerful tools used by thousands of professionals worldwide.

Perfactory Family

Designed for real production and build sizes up to 253.6 cubic inches, EnvisionTEC “personal factory” line of 3D printers uses exclusive DLP processes and offers the ability to run lights-out production.

First launched in 2002, the Perfactory isn’t just an icon in the 3D printing world – the printer on wheels — it’s a trusted and reliable one. EnvisionTEC have longtime users who call just to say hello, and let us know that they’ve never had to ring us up for service.

Designed for real production and build sizes up to 253.6 cubic inches, EnvisionTEC “personal factory” line of 3D printers uses exclusive DLP processes and offers the ability to run lights-out production.

First launched in 2002, the Perfactory isn’t just an icon in the 3D printing world – the printer on wheels — it’s a trusted and reliable one. EnvisionTEC have longtime users who call just to say hello, and let us know that they’ve never had to ring us up for service.

CDLM Printer Family

EnvisionTEC launched their Continuous Digital Light Manufacturing technology in early 2016 with the Micro Plus cDLM. It’s based on a patent-protected approach EnvisionTEC came up with a decade ago.

A twist on the EnvisionTEC DLP technology, this process allows for continuous motion of the build plate to deliver exceptional build speeds. While the first EnvisionTEC cDLM printer was developed with EnvisionTEC loyal jewelry customers in mind, don’t worry – they have more coming.

EnvisionTEC launched their Continuous Digital Light Manufacturing technology in early 2016 with the Micro Plus cDLM. It’s based on a patent-protected approach EnvisionTEC came up with a decade ago.

A twist on the EnvisionTEC DLP technology, this process allows for continuous motion of the build plate to deliver exceptional build speeds. While the first EnvisionTEC cDLM printer was developed with EnvisionTEC loyal jewelry customers in mind, don’t worry – they have more coming.

3SP Family

So, you need big, heavy-duty parts? EnvisionTEC has got you covered with their 3SP technology, which uses a UV laser to scan, spin and selectively photocure resins into large, durable parts up to 5800 cubic inches.

You don't need to sacrifice accuracy or surface finish to make big 3D objects with 3SP. A true industrial 3D printer, the EnvisionTEC 3SP line is equally at home on a factory floor as it is in a machine shop, hospital, or laboratory.

So, you need big, heavy-duty parts? EnvisionTEC has got you covered with their 3SP technology, which uses a UV laser to scan, spin and selectively photocure resins into large, durable parts up to 5800 cubic inches.

You don't need to sacrifice accuracy or surface finish to make big 3D objects with 3SP. A true industrial 3D printer, the EnvisionTEC 3SP line is equally at home on a factory floor as it is in a machine shop, hospital, or laboratory.

The 3D-Bioplotter Family

A recognized world leader in biofabrication, EnvisionTEC’s 3D-Bioplotter family of bioprinters is being used for groundbreaking medical research and manufacturing, such as organ and tissue engineering, among other amazing things.

With three levels of functionality, this printer family processes open-source biomaterials using air or mechanical pressure to a syringe, which can fabricate scaffolds. These printers have been designed for use in a sterile biosafety cabinet. Build sizes up to 192.4 cubic inches.

A recognized world leader in biofabrication, EnvisionTEC’s 3D-Bioplotter family of bioprinters is being used for groundbreaking medical research and manufacturing, such as organ and tissue engineering, among other amazing things.

With three levels of functionality, this printer family processes open-source biomaterials using air or mechanical pressure to a syringe, which can fabricate scaffolds. These printers have been designed for use in a sterile biosafety cabinet. Build sizes up to 192.4 cubic inches.

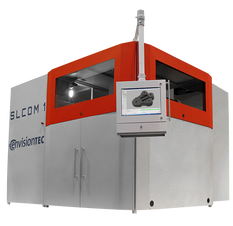

SLCOM

This groundbreaking 3D printer for composites launched with the SLCOM 1 in early 2016. EnvisionTEC Selective Lamination Composite Object Manufacturing (SLCOM) technology additively manufactures woven fiber composites preimpregnated with thermoplastics using a propriety method.

It automates production of composite parts with amazing surface finish and X-Y strength. A wide variety of fiber and thermoplastic material choices, and mixes, are available. We believe this innovative machine, which can build objects up to 10 cubic feet, will change the face of composite manufacturing.

This groundbreaking 3D printer for composites launched with the SLCOM 1 in early 2016. EnvisionTEC Selective Lamination Composite Object Manufacturing (SLCOM) technology additively manufactures woven fiber composites preimpregnated with thermoplastics using a propriety method.

It automates production of composite parts with amazing surface finish and X-Y strength. A wide variety of fiber and thermoplastic material choices, and mixes, are available. We believe this innovative machine, which can build objects up to 10 cubic feet, will change the face of composite manufacturing.

Viridis3D

This Robotic Additive Manufacturing technology, used in the marketplace today, offers a unique, high-quality and economical solution to the foundry industry – fast 3D printing of sand molds and cores from a CAD file. An exclusive binder jetting technology, packaged in a print head attached to an ABB robot arm. Currently offers XL build sizes up to 6 cubic feet. It’s also the fastest, most flexible robotic 3D printing platform in the casting industry.

The first product in this series, the Viridis3D RAM 123 uses less sand and is substantially less expensive than other sand casting 3D printers on the market today.

This Robotic Additive Manufacturing technology, used in the marketplace today, offers a unique, high-quality and economical solution to the foundry industry – fast 3D printing of sand molds and cores from a CAD file. An exclusive binder jetting technology, packaged in a print head attached to an ABB robot arm. Currently offers XL build sizes up to 6 cubic feet. It’s also the fastest, most flexible robotic 3D printing platform in the casting industry.

The first product in this series, the Viridis3D RAM 123 uses less sand and is substantially less expensive than other sand casting 3D printers on the market today.