|

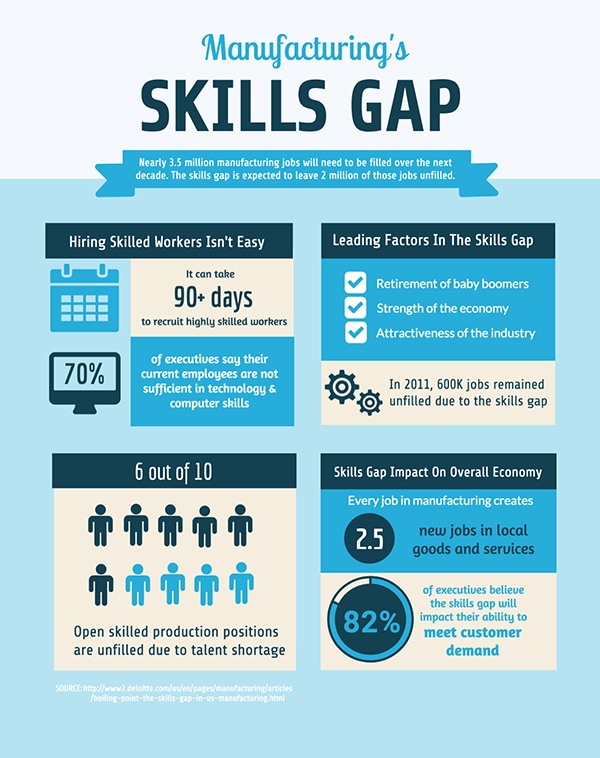

This article original appeared on Ganesh Machinery's Blog.  DID YOU KNOW that over the next decade more than 3.5 million jobs will need to be filled? And according to The Manufacturing Institute, we will only be able to fill roughly 1.5 million of those jobs. With all of those jobs left unfilled, you can only imagine how many companies will get left behind because they lost the ability to produce. Take a look at the harsh reality we’re facing: Every year we see more reports and forecasts urging manufacturers to do something about the skills shortage. It’s time for us to do our part and we want to empower you to keep manufacturing alive and well in America. It starts with the youth.

In December, we did just that. We donated our robust GT-1640 lathe to Simi Valley School and Institute to support their machinist training program. “The GT-1640 is ideal for this type of work because it is a powerful and precise lathe. It is also the type of machine students can expect to see when they enter the workforce,” said Simi Valley Lead Instructor Oygar Lindskog. >>Read the full story here. While it may seem like giving away a machine is a big chunk of change, we know it will pay off in the long run. It’s our contribution to educating and invigorating people so that manufacturing continues to grow and thrive in America for generations to come.

As passionate manufacturers, we want to see our industry grow and help incoming generations succeed. Let’s work together to make that happen.

0 Comments

Article originally appeared on Te-Co's Blog. It’s no secret U.S. students lag behind in math and science courses compared to many countries in Eastern Asian and Europe. Studies show it’s not just children who struggle with the subject: Between 50-89 percent of Americans suffer from some sort of math anxiety, and only 45 percent of high school graduates in 2011 were prepared for college-level mathematics.

The gap in understanding mathematics isn’t new in America, but more initiatives to combat this gap are popping up. It started in 1986 when April became known as Mathematic Awareness Month to encourage the study and increase awareness of mathematics. “The application of mathematics is indispensable in such diverse fields as medicine, computer sciences, space exploration, the skilled trades, business, defense, and government,” then-President Ronald Reagan said. “To help encourage the study and utilization of mathematics, it is appropriate that all Americans be reminded of the importance of this basic branch of science to our daily lives.” We know mathematics is vital—especially to us in the manufacturing industry. Without simple triangles and calculations we would not be able to design, program and machine the parts we sell. Being able to solve problems using algebra, geometry and trigonometry is at the core of our manufacturing processes. Utilizing mathematics is actually important to every aspect of our business. We us mathematics in selling, manufacturing, inspecting, and yes even counting the money made. But how can we expect to continue growing our manufacturing when students are struggling to meet these standards? Well, even more change is happening. Curriculum restructuring in many states across the country is adapting and suiting the specific needs of students while adhering to regulated guidelines. They not only study math skills but the concepts behind them along with applying mathematical reasoning. Plus, there are a slew of online tutorials and resources to aid the learning process. We are tapping into new resources, challenging ourselves, and expanding our brainpower—much like we do every day at TE-CO. Don’t fret, because U.S. manufacturing isn’t going anywhere. With many companies choosing to manufacture their products stateside, sales increasing, and manufacturing turning digital, the industry has been steadily rising. A new report from Georgetown University estimates there will be more than three million new manufacturing jobs available by 2018. Those are some good numbers to add up, right? We think the scope and process of mathematics is changing along the technology it is computed on, and we can’t help but be excited for the future of the subject matter and the positive impact it will have on the industry, our jobs, and our company. |

AuthorHere you will find the latest breaking news from manufacturing as well as the newest product introductions and promotions Archives

July 2017

Categories

All

|

HoursM-F: 8am - 5pm

|

Telephone319.329.8134

|

|

©2023 Abrasive Innovations. All Rights Reserved

RSS Feed

RSS Feed