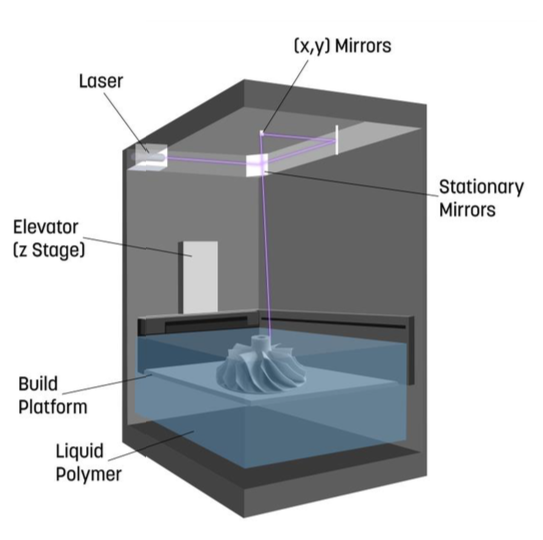

This article examines the difference between traditional SLA, DLP and 3SP for additive manufacturing in a large build envelope when high accuracy, repeatability, reliability and throughput are required. After more than three decades of research and development, 3D printing is ready for prime time in manufacturing — production of high-value parts and mass customized products, in addition to prototypes, injection molding tooling, end-of-arm tooling and assembly jigs and fixtures. In fact, a variety of manufacturers have been using 3D printing, also known as additive manufacturing, this way for years now, with more adopting the technology every day. In addition to manufacturers of all sizes, the range of production users also includes laboratories, hospitals and Hollywood studios. Did you know, for example, that the global hearing aid industry has been mass producing custom hearing aids with 3D printers for more than a decade1? In recent years, dental laboratories have also been mass producing dental and orthodontic models, which require high XY accuracy and a smooth surface finish. This has eased the way for the mass production of clear thermoformed aligners for teeth straightening, in addition to other dental products. And in 2016, General Electric began mass production of metal fuel nozzle injectors for its LEAP jet engine using 28 additive manufacturing machines — validating the idea that 3D printing isn’t just for prototypes anymore. Vat photopolymerization, in which a light source is used to selectively cure or harden photopolymer resins inside a vat or tray, has become a popular method of 3D printing among manufacturers for a variety of reasons. For example, the photopolymer resins used during this process are also known as thermosetting plastics or thermosets, which strengthen during post-curing and hold their shape, even after reheating. This is in contrast to thermoplastics, which can be re-melted after being formed into a part. A wide range of thermoset materials are also available today with a variety of desirable properties, such as epoxies, which offer elasticity and exceptional chemical resistance, as well as biocompatible materials. The vat photopolymerization category includes stereolithography (SLA), digital light processing (DLP) and a new method launched in 2013 called 3SP for scan, spin and selectively photocure. 3SP specializes in affordably building accurate parts with a smooth surface finish across a relatively large build envelope, where traditional SLA and DLP have challenges scaling up in size affordably. This allows for 3D printing of a single large part or a tray of smaller parts. To understand why 3SP is so unique in its benefits, it’s critical to understand the limits of SLA and DLP. Understanding SLA vs. DLPOne of the earliest forms of 3D printing, SLA was patented in 1986 and commercialized by 3D Systems. In SLA systems, a UV laser beam literally draws — lithography means “to write” — out a part into a vat of resin. Wherever the light hits resin, curing or hardening occurs. The laser beam can be positioned either above or directly below the vat, and each approach has its own pros and cons. However, for most large manufacturing systems, the laser is typically positioned above the vat and curing takes place on the upper layer of resin in the vat or tray. This approach allows for the largest build envelopes and lower gravitational forces on the part being built. After each layer is built onto a build platform inside the vat, the platform is lowered in the Z axis so the next layer can be cured onto the part. SLA’s Limitations Expensive to Correct However, there are two main problems with traditional SLA in large build environments, whether one is building a single large part or a full build envelope of smaller parts. The first is speed. Drawing out a big part or a collection of parts in SLA with a laser beam, layer by layer, is akin to drawing each layer on a sheet of paper with a fine-point pen. Each layer must be outlined and filled in perfectly with the laser beam. The bigger the build project, the longer the process takes.

Over the years, manufacturers have figured out ways to try to minimize this focus distortion by using mirrors controlled by galvanometers, also known as galvo mirrors, often in concert with optical lenses, to reflect the laser beam to further points in the build envelope and simultaneously reduce distortion or flatten the field at point of impact with the resin. Some of these large build-envelope systems also use multiple laser beams and a variety of galvo mirror and optical lens systems. While these systems are effective, the complexity of these systems also increases their price, sometimes dramatically. For example, the ProX 950 from 3D Systems uses two lasers working simultaneously in a build envelope of 1500 x 750 x 550 mm (59 x 29.5 x 21.65 in.) While the system is highly accurate, it also retails for just under $1 million. The company’s ProJet 6000, which offers uses a single laser and a build envelope of 250 x 250 x 250 mm. (10 x 10 x 10 in) retails for about $200,000. What’s more, the complexity of these expensive systems can also amplify speed challenges. Instead of drawing out the image with a fine-point pen, these galvo mirror systems are more akin to drawing out large parts with an Etch a Sketch controlling a reflecting beam, or drawing point, in X and Y.

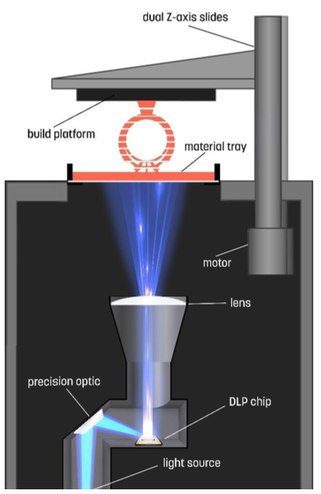

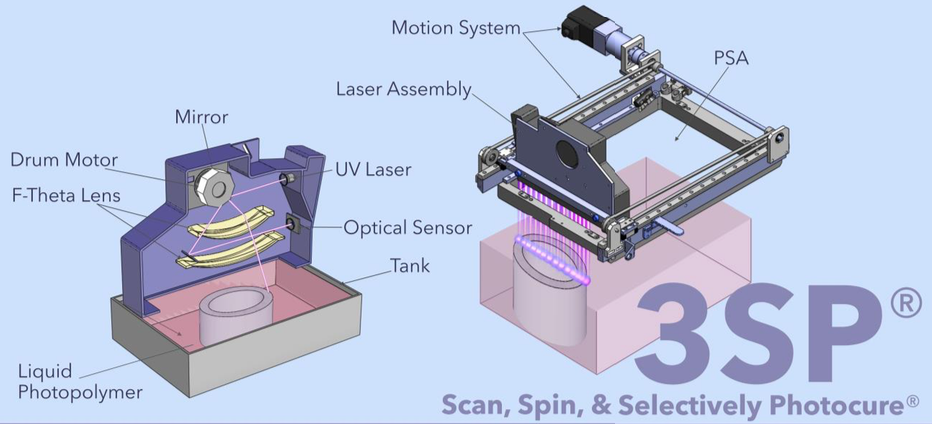

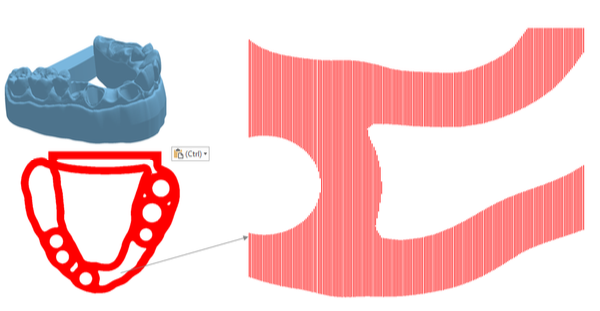

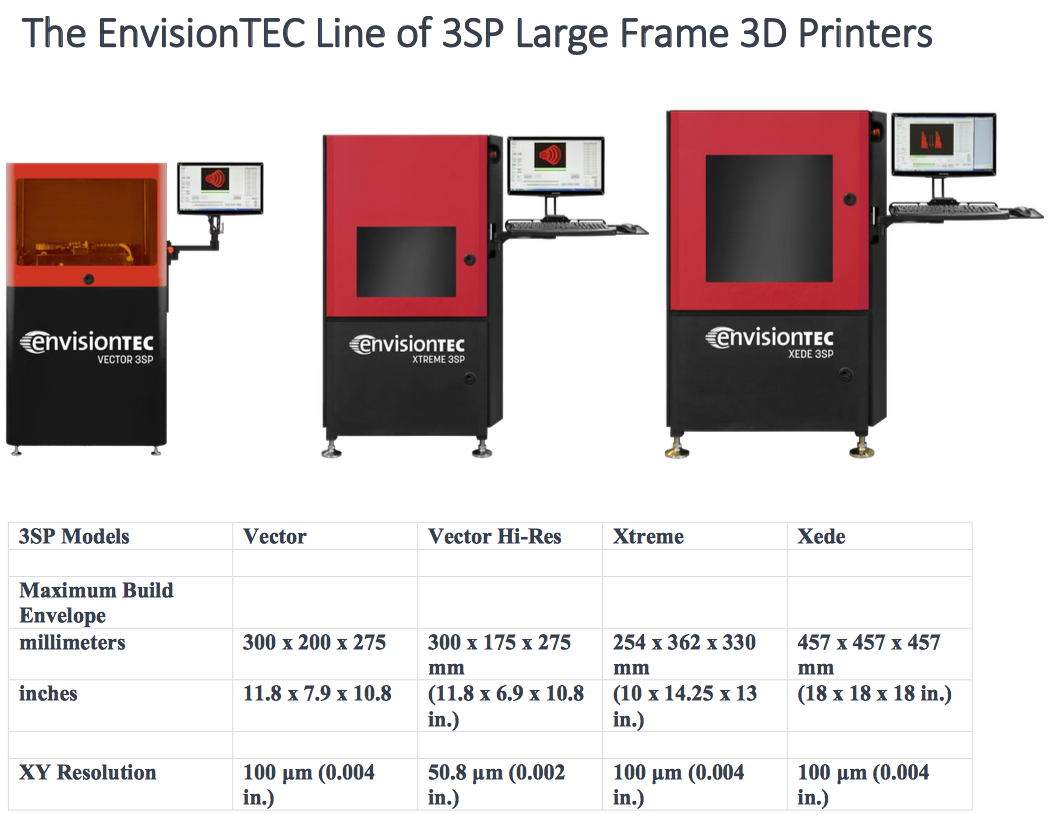

This is a photograph of the EnvisionTEC Enhanced Resolution Module (ERM), which moves a projector, seated in the middle, a half pixel in X and Y, to slightly shift the second exposure in its DLP machines and reduce stairstepping in a sophisticated 3D anti-aliasing technique. This is a photograph of the EnvisionTEC Enhanced Resolution Module (ERM), which moves a projector, seated in the middle, a half pixel in X and Y, to slightly shift the second exposure in its DLP machines and reduce stairstepping in a sophisticated 3D anti-aliasing technique. Pixels Reach Their Limits For example, the largest high-definition projector size currently available for 3D printer manufacturers is 1920 x1200 pixels. With that projector, EnvisionTEC offers the largest DLP build envelope in the 3D printing industry, at 192 x 120 x 230 mm (7.6 x 4.7 x 9.06 in). In that system, there are 10 actual pixels in X for every 1 mm or 0.39 inches. The reason EnvisionTEC can offer a larger build envelope than its DLP competitors is because of its patented Enhanced Resolution Module, or ERM, technology. The ERM is an electromechanical system that moves the projector a half pixel in X and Y during a quick second exposure layer that anti-aliases the edge of the build object. That means its system delivers a surface quality that appears as if it were printed with twice as many pixels. Still, if one tries to scale up a DLP system to larger sizes than 192 x 120 x 230 mm, surface quality begins to erode quickly. Without a higher definition projector system, or another technological innovation, DLP has found its upper build limit for quality parts. Understanding 3SP In a desire to meet customer demand for larger parts, while preserving part accuracy and surface finish, EnvisionTEC set out to develop an affordable solution. Understanding the limits of projectors, the engineering team at EnvisionTEC started with the idea of a laser beam that, instead of being fixed as in most SLA systems, actually travels over the resin tray to reduce the need for a variety of expensive lasers, galvo mirrors and optics. The R&D team also wanted to draw out images in a more efficient manner. The patented 3SP machine design is unlike anything on the market, offering a simple and affordable solution for 3D printing quality parts on a large build tray. The key to the system is packaged in a special moving 3SP gantry that spans nearly the full Y axis of the build envelope. Within that gantry, a multi cavity diode laser is housed in an upper chamber. Rather than use galvo mirrors, the laser beam is reflected off a mirrored drum that spins at up to 20,000 RPM and directs the beam through a series of two concave custom- designed F-theta optical lenses. These thin F-Theta optical lenses work very much like a pair of progressive eyewear lenses, flattening the focus of the beam at its exit point. In the case of the 3SP machine, the focus is flattened directly above the point of impact with the resin, eliminating the distortion that challenges accuracy and surface finish in traditional SLA systems. 3SP’s Quick-Drawing System The way the 3SP system “draws” out a part is also different than in typical SLA machines, which sketch a single beam around the build envelope in X and Y. The 3SP system moves more like a 2D laser printer, essentially drawing out a full Y axis at a time before advancing to the next position.

The speed of the motor can also be reduced to allow the beam to move more slowly and more deeply penetrate or cure resin when desired, and the system delivers exceptional XY resolution.In all, the build speed for the entire build envelope is 10 mm depth per hour, and the build time is not dependent on the X-Y volume of the build envelope being built, but rather the Z axis alone.

Each layer takes the same amount of time to build. So while SLA can take longer, for example, if more items are on the build envelope, 3SP takes the same amount of time regardless of build plate coverage, resulting in rapid production. What’s more, the multi cavity diode laser used in 3SP is at least five times more affordable than a solid state laser employed by most competing industrial SLA systems. It also allows for the 3D printing of high viscosity materials, including filled materials.

1 Comment

|

AuthorHere you will find the latest breaking news from manufacturing as well as the newest product introductions and promotions Archives

July 2017

Categories

All

|

HoursM-F: 8am - 5pm

|

Telephone319.329.8134

|

|

©2023 Abrasive Innovations. All Rights Reserved

RSS Feed

RSS Feed